We can produce a variety of styles and colors, and we can do the ultimate in each product and color!

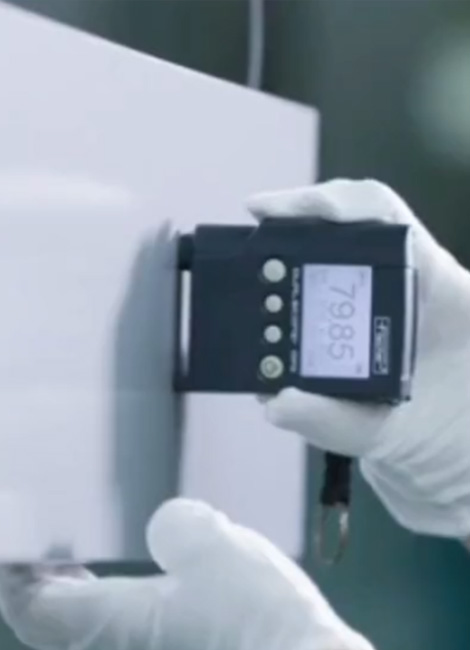

Multiple inspection processes, including station self-inspection, quality inspection inspection, full inspection, sampling inspection, etc..

According to the product inspection instructions, including the adaptation of the product with each angular curvature of the product, smoothness of appearance, strain scratch welding erosion detection, abnormal surface of color paint, performance tension, load-bearing water resistance test, etc.. Strive for quality, excellence, and the final product is qualified and packaged into storage.